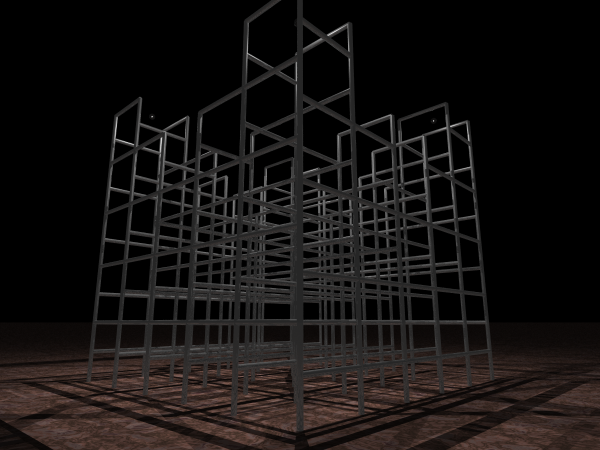

Pipe Dream is a modular climbing structure made from 1.25" bore steel tubes joined with cast iron screw-on rail fittings. It measures 20'×20' at its base by 21' tall at its outer towers, and weighs in over two tons. Read here about its design or see more about our installations.

We really loved the honey trap at Burning Man 2010, and wanted to build a similarly pleasant and beautiful object for people to climb around on. In the past we've only worked with lumber, and burned our projects when done. This year we wanted to make something out of parts we could reconfigure and reuse for future projects.

We quickly settled on tube steel for its availability and strength to weight, but needed a way to join the pieces. We could weld them in place and chop them apart later, but that seemed messy and time consuming, and realistically is beyond our metalworking skills.

I first noticed Speed-Rail fittings on some random handrails in the Presidio, and got the crazy idea we might be able to use those. After some more research we settled on Kee Klamp fittings. Unlike many rail fittings, these are cast iron, so we avoid aluminum-on-steel corrosion. They attach using tensioned set screws rather than pin and socket joints, which would require a lot of drilling.

We had major concerns about whether rail fittings would be good primitives for building a structure. After testing, we think they're safe enough to try at Burning Man 2011, and will let our experience there be the judge.

Opinions on the Internets seem mixed. Some people say it's a terrible idea to use anything but scaffolding for rigs. Others say they've done Kee Klamp rigs and lived. Some people in Ghana built a church with Kee Klamp fittings, and some other dude designed a barn.

The specs say the fittings are rated for 2000 lbs. of axial load per set screw (2:1 safety), which makes sense because you don't want a railing to snap when you're leaning on it. The radial forces are trickier. For #7 pipes over a 4' span, the fittings can carry 1379 lbs. (1.66:1), so a single strut can support as many climbers as fit on it, as long as the columns are rigid.

I did some quick column buckling math to see that one #7 20' tube can support about 1000 lbs. (4380 N), which is pretty amazing. An array of such tubes spaced at 4' can definitely hold a bunch of struts and climbers. The question is just whether the array will stay upright, especially given we can't have a foundation on the Playa. This is mostly a function of the geometry and load distribution on the structure.

We used SketchUp to draw out our design ideas. Our structure had to have

I liked a hex pyramid design which had many beautiful symmetries:

Igor favored a more random forest of boxes. Boxes are a bit more practical than hexes because the cheapest and most readily available fittings have right angles. Plus he figured a really regular structure could be boring.

Talking some more through it, we realized a) we needed rigid unbroken columns, b) this thing was going to be pretty expensive, c) we did not want to use lots of different lengths of pipe and kinds of fittings, or it would get too confusing. We decided on struts of no more than 4' and columns no taller than 21' (the size of an uncut tube). This and our span distance gave us a straw man design, the Big-Ass Cube, a 4' lattice in two 2' offset grids in different planes (see picture). We figured this would cost about $10,000 and we could probably do it.

A pyramid probably would've been a logical next step from there, and would likely be the safest geometry for its height. But because I'm crazy, I opted for the opposite and took a roughly pyramidal chunk out of the top of the Big-Ass Cube.

This inverted pyramid design is less stable structurally, but has many practical advantages. The 12' central tower lets us tack bigger pieces in a balanced way onto a structure which already has smaller ones standing up. It also let us start with small tests and build out taller sections as we gained confidence.

It's also nice to have a chill space in the interior, and we hope having four observation towers at opposite corners will tend to spread dynamic load around the structure instead of concentrating it.

Finally, if things go really badly, we can take down the four outside corner columns to eliminate the most dangerous places on the structure, or take down the outer walls entirely and still have a 12' jungle gym.

With a few tweaks, this is basically the shape of Pipe Dream.

At first we thought we'd just buy a bunch of 21' tubes from a foundry, and cut and store them ourselves somewhere in the back yard. We bought a hand pipe cutter for conduit off the Internet. This tool barely scratched the surface of a #7 tube. Also our lanlord was not happy about us using the yard to store and build a big project.

It's hard to transport a 21' tube. They weigh about 50 lbs., and do not fit easily (or even uneasily) into a 12' Toyota Tacoma with a 6' bed, like the kind you might rent from your local carshare service. You can sort of take 16' lengths, but it is not a fun drive.

We ended up getting all our pipes cut to order from a plumbing supply place in Bayview in San Francisco. We don't really speak Mandarin and they don't really speak English, so diagrams and numbers helped a lot with this. They have a giant ten ton tool for cutting pipes, and charged us $1 per pipe cut, which was well worth it.

For fittings, we contacted the west coast distributor for Kee Klamp, Davis Bacon. We first placed some smaller orders, then ordered a large batch when we were sure we wanted to go ahead. The big order had to come straight from a factory in LA. It arrived in a 55 gallon drum on the sidewalk outside our house, with an extra fee for not having a loading dock. In all we probably have 400–500 lbs. of fittings in 30 lbs. plastic sacks.

We made all kinds of mistakes counting and ordering, and had to rush to backfill a few times. It helped to make a careful schematic diagram in addition to our 3D model, but we made mistakes in that, too, and still got confused during planning and assembly.

We stored the initial batches of pipes and fittings in our back yard, but this really didn't scale. When it came time to do a full test build, we rented some time in the yard at NIMBY in Oakland. We carried the full pipe order and all the fittings there in a rented 24' stakebed truck. Thankfully, we were also able to work out a deal with them to store and ship the pipes to us on the Playa.

We test built the structure in phases, working from the center out to learn how the materials would behave and ordering more parts as we grew more confident. Because we're all pretty busy, we did this as three big tests on weekends a month or so apart.

Our first test was to figure out whether Kee Klamp fittings would hold pipes together at all. We started by erecting a tower of four 12' tubes in the back yard with a couple of struts. Four of us climbed all over it and shook it around. We were pleasantly encouraged by how rigid it felt, and left it up for a few days without incident.

Our next test was to establish how we could compose towers, and whether the structure would remain sturdy as it got larger. We needed a space bigger than our yard, so we rented a pickup and carried more pipes to a vacant parking lot where truckers hang out at Heron's Head Park. This time we built a 2×2 section of the full 5×5, starting with and adding to the center tower.

We learned that we could add both planes and corners onto towers. To add a plane, we build a "ladder" on the ground with struts connecting two columns and other struts sticking up into the air; then we hoist this ladder up to meet a face of the tower and stick the loose ends into the appropriate sockets. This gives us two towers.

Corners are trickier. We attach struts to one tube on the ground, keeping half on the ground and rotating the other half into the air. We then lift the column and stitch the loose struts alternately into two planes of sockets on two towers. We weren't sure we'd be able to do that, and had worked out a complicated method using crossover fittings in case it was not possible. Thankfully there's enough play in the fittings.

Generally we were pretty pleased with our second test, but were concerned the structure was too easy to shake. We decided that this was because our staggered grids created too large an unbraced span at the base. To remedy this, we added a full grid at 2', which helped a lot.

Our final test was to see how hard it was to build the whole thing, and what it felt like as it grew to full size. It was a lot of hard work lifting pipes, and six people working for two afternoons were not able to finish everything. Still we erected most of the structure, including two outer towers, and took the thing down again. With what we learned, we felt we could do it easily on the Playa.

We spent a lot of time packing and unpacking, measuring and marking pipes. We also refined our technique a lot, so everyone now gets how to make corners and ladders reliably. We learned that hoisting sections up with rope gives a lot of advantage. We also learned it's pretty silly for fewer than four people to attempt to take down or put up an outer section.

The central 3×3 felt rock solid, but if you tried to you could shake the rest of the structure from atop the two outer towers. It definitely wasn't coming up or apart, and you had to actively try to shake it, but it still shook, for a couple reasons. The fittings have a few degrees of give for each of the 16'+ columns, which lets them displace a few inches. NIMBY's yard, where we were building, is gravel, much looser pack than Playa. Based on comparing to our previous test on asphalt, we think this will get better on hard pack soil.

In summary after testing I feel pretty confident taking this thing to Burning Man, and think it will not fail catastrophically. I'm concerned about the towers but we'll see how it behaves on the Playa, and scale back if needed before crowds start hanging out on it.

We have some large panels of brightly colored spandex nylon which we want to cut into triangles and stretch in places in the structure, to create interesting shade and texture. Over the center tower there will be a large chandelier made from LED bulbs and diffuse plastic cubes, and there will also be lights at each corner tower, so that the whole structure is brightly illuminated at night.

Our plans also call for platforms at 16' in each corner tower. We tested one of these platforms in our NIMBY build, and found that it worked ok. The platforms we have made are just slats on 2×4s which rest atop a square of 4' struts. We may still refine these some more. One issue is that neither the platforms nor the struts they rest on have four true right angles. They also look somewhat incongruous, being made of wood and all, and may encourage lots of people to congregate at the towers which may be more hazardous than it is worth. One alternative option is rope netting.

We'll have signs explaining that you may die if you attempt to climb Pipe Dream.

Even though it's Burning Man, and you sign your life away to get in, we're still strongly considering liability insurance.

Igor had the excellent notion to make a time lapse movie of our construction efforts.

I ordered some Dayglo paint and tried painting a pipe, since we figured it might be cool to have them fluoresce under UV lights at night. The paint was kind of flakey and moop-y, so we judged it better not to try to paint them and get crap all over the earth. Anyway the plain steel is quite beautiful.

Many folks have expressed concern that the structure will get too hot to climb comfortably during the day. The pipes did not heat up much during our 80 degree Fahrenheit build days at NIMBY, and we will have some shade. Actually though, they're pretty reflective, so I worry more that they'll be cold to the touch at night. There is not a lot we can do about that.